Heavy Equipment Repair Software that Drives Consistent Shop Growth

Don't make managing your heavy equipment repair shop harder than it needs to be. Manage it in less time and without the daily hassle with ShopView.

Start Free TrialGet Jobs Done Faster with Simplified Service Order Management

Go from assignment to invoicing in a fraction of the time with ShopView. Managing your heavy equipment repair operations has never been easier.

End-to-End Order Tracking

Manage service orders in a straight line from intake to completion. Every step is clearly recorded to avoid delays and cost slippage.

Time-Saving Automation

Save hundreds of hours each month and reduce human error by automating routine tasks like scheduling and updates.

Simple Service Histories

ShopView makes creating comprehensive service histories easy so you can quickly refer to them to improve customer service.

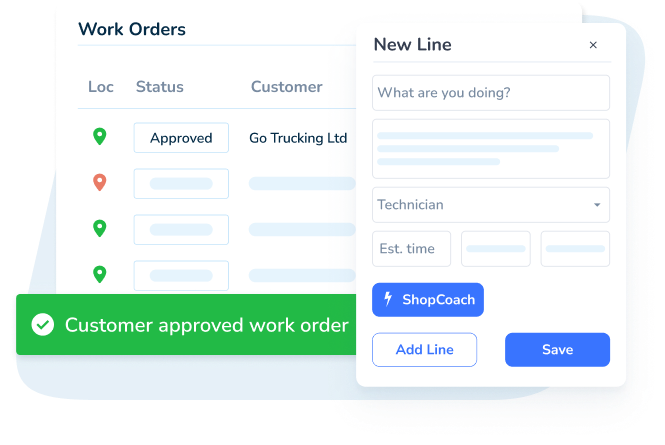

Fastest Work Order Build-Out in the Industry

Optimize your shop with ShopView's advanced software, designed specifically for heavy equipment repair businesses.

Learn More About Our Work Order Features

Simple & More Accurate Inventory Control

ShopView makes inventory control for heavy equipment repair shops less time-consuming and eliminates human error. It's inventory control, without the effort.

Real-Time Parts Tracking

Monitor inventory levels in real-time to maintain accuracy and avoid disruptions due to stockouts.

Automated Reordering

Automated reordering keeps inventory at optimal levels, saving you money by decreasing overstocking or shortages.

In-Depth Reports & Alerts

Generate detailed reports with just a few clicks about inventory levels, usage patterns, and reordering needs to optimize your stock management.

Improve Customer Uptime

ShopView's heavy equipment repair software helps you maximize the uptime of your customer's fleets, ensuring smooth operations and increased productivity.

Learn More About Our Uptime SolutionsAccurate Invoicing & Fast Payments

ShopView's all-in-one invoicing and payments for heavy equipment repair shops speeds up the time it takes to get paid.

Custom Invoicing

Elevate your professionalism by creating tailored invoices that reflect your brand and provide clear, detailed billing information for your clients so you get paid sooner.

Precision Billing

Create more precise invoices by automatically calculating the cost of parts, labor, fees and taxes to reduce discrepancies and billing disputes.

Seamless Integration

ShopView connects with your existing accounting and business systems for fast, integrated invoicing, reducing the time spent on financial admin.

ShopView is the #1 Way To Make Your Shop More Efficient & Profitable

Run a more profitable shop with the easiest to use management system on the market. Built by repair shop operators just like you.

Designed for Ease of Use

Easy adoption with minimal training required allows your heavy equipment repair shop team to start using the software quickly.

Full Support From Industry Specialists

Comprehensive onboarding ensures your repair shop team is fully equipped to use the software from day one.

Unbeatable Integration Capabilities

ShopView seamlessly integrates with existing systems in your heavy equipment shop, allowing for a smooth transition and minimal disruption.

Built By Heavy Duty Shop Owners Who Know the Grind

Our team has 20+ years of collective experience in heavy-duty repair. We built ShopView to address the real challenges we faced running our own shops - from work order chaos to billing headaches to technician productivity.

"ShopView made our shops more productive and efficient - and it will do the same for yours."

See How ShopView Helps Heavy-Duty ShopsWhy Choose ShopView?

Available on All Devices

Simple to set up and use on computers, smartphones and tablets. Your data syncs across all devices in real-time.

Seamless Integration

Connects with accounting and business systems you already use, including QuickBooks, IBS, and more.

Comprehensive Support

From onboarding to ongoing support, reach out anytime for help. We guarantee a response within 12 hours.

Heavy Equipment Repair Software: Keep Your Machines Working and Your Shop Profitable

Introduction

If you've run a grader, a loader or an excavator, you know that every minute counts. When a piece of heavy equipment sits in your yard waiting for parts or approvals, it's not just metal collecting dust; it's lost money.

Research shows unplanned downtime consumes approximately 20-30% of a machine's available hours. Fleet experts estimate that a single truck out of service can cost between $448 and $760 per day in lost revenue and extra expenses. For construction equipment or agricultural machinery, the daily cost can be even higher.

Why Your Shop Needs Heavy Equipment Maintenance Software

Heavy equipment repair software pulls every part of your operation into one platform. You can create a multi-machine work order, schedule the right technician, track every part and fluid, capture labour time accurately and send a clean invoice when the job is done.

It's built for the kinds of machines that keep roads, farms and construction sites running. Generic software doesn't understand the complexity of a skid steer with multiple attachments, a hydraulic hammer and a service truck all in one job. Purpose-built software does, and it keeps your office and shop floor in sync.

Why Paper and Generic Tools Hold You Back

Using paper or a generic auto program might feel familiar, but it costs you money every day:

- Lost Labour - Digital time tracking typically recovers about 1.5 hours per technician per day. At typical labour rates of $130, that's nearly $200 per technician daily.

- Parts Problems - Spreadsheets and handwritten lists lead to parts going missing, cores never returned and unnecessary reorders.

- Scheduling Issues - Paper calendars don't update when parts are backordered or when customers approve additional work.

- Compliance Burden - Heavy equipment shops juggle more paperwork than auto shops, including DOT inspections, OSHA safety forms, emissions records and recall documentation.

- Cash Flow Delays - Manual invoicing processes often add 7-10 days to the cash-collection cycle.

Features That Actually Help You

- Multi-Asset Work Orders - Create one work order with separate line items for each unit

- Digital Time Clocks - Technicians tap start when beginning a task and tap stop when finishing

- Inventory Management - Barcodes or RFID tags let you check parts in and out without flipping through a binder

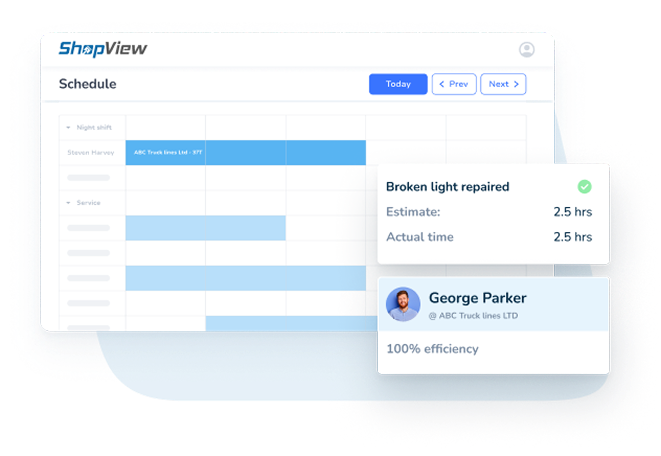

- Visual Scheduling - Colour-coded calendar shows bays, technicians and field service trucks

- VIN/Serial Decoding - Software pulls the machine's make, model and engine details

- Digital Compliance - Easy for technicians to record data and capture photos

- Mobile Apps - Over 80% of shops offer mobile services; field technicians receive work orders even without cell signal

Why It's Worth the Investment

Digital time tracking typically recovers about 1.5 hours per tech per day. At typical labour rates of $130, that's nearly $200 per technician daily. Over a month, recovered revenue adds up significantly.

- Reduced Downtime - Digital scheduling backed by preventive maintenance can cut downtime from 20-30% to around 5%

- Inventory Control - Tight tracking reduces shrinkage and eliminates ghost stock

- Core Recovery - Tracking ensures you get credit for rebuildable components

- Faster Payments - Same-day invoicing shrinks accounts receivable. Digital payment options let customers pay online as soon as they approve

- Complete History - Digital records provide complete history of every repair, inspection and part installed

Real Shops, Real Results

Independent shops across North America are using heavy equipment software and reporting real gains:

- One Canadian operation achieved 100% technician productivity, saved over ten hours per week at the front counter and captured around $15,000 in extra revenue each month

- Another shop cut turnaround times significantly by reducing missing parts and improving communication

- Smaller shops report two extra billable hours per day, stockrooms no longer overflowing with duplicate parts, and fewer after-hours calls between service writers and field techs

External data shows small fleets are quickly adopting data-driven tools, with technology readiness scores rising significantly.

How to Pick the Best Heavy Equipment Software

- Feature Fit - Multi-asset work orders, core tracking, field service support, attachment management

- Ease of Use - Intuitive to start using with minimal training

- Comprehensive Platform - Work orders, time tracking, parts management, scheduling, estimating, invoicing, reporting and compliance

- Integrations - QuickBooks, parts suppliers, telematics systems, payment processors

- Transparent Pricing - Ask about monthly fees, user limits, setup costs and contract terms

- Security - Encryption, regular backups and compliance with privacy laws

A Practical Implementation Plan

- Document Workflow - Write down each step: intake, diagnosis, parts ordering, repair, quality check, billing and follow-up

- Demo Multiple Vendors - Use your own scenarios during the demonstration

- Clean Your Data - Compile customers, machines, attachments and parts, removing duplicates

- Pilot First - One technician or one bay, running actual jobs through it

- Short Training Sessions - Specific tasks with cheat sheets

- Gradual Expansion - Add more technicians and modules once stable

- Set Goals - Reduce unbilled hours by 10%, increase parts margin by 5%, cut invoice turnaround time in half

Keeping Your Fleet Customers Coming Back

Heavy-equipment repair isn't just about wrenches and grease; it's about customer relationships. When you help contractors and farmers avoid downtime, you earn their loyalty.

- Customer Portal - Approve estimates, track repair status and pay invoices online

- Text and Email Updates - Show you respect their time

- Photos and Notes - Showing worn parts and detailed notes in estimates builds trust

In a competitive market, these small touches make a big difference.

Conclusion: Digitize Now, Reap the Rewards

Purpose-built heavy equipment repair software pulls everything together - work orders, parts, labour, scheduling, compliance and billing - so you get paid for every minute and every part.

Data from independent research proves that embracing digital tools recovers lost revenue and cuts downtime. The market for maintenance software is growing fast because shops see results.

Look at your workflow, test a system built for heavy equipment and talk to peers who have done the same. When your machines keep moving and your books balance faster, you'll wonder why you waited so long.

Ready to Increase Your Shop's Revenue by 20%+?

Join thousands of heavy-duty repair shops that trust ShopView to manage their operations profitably.