Parts Inventory Made Simple, Accurate, and Profitable

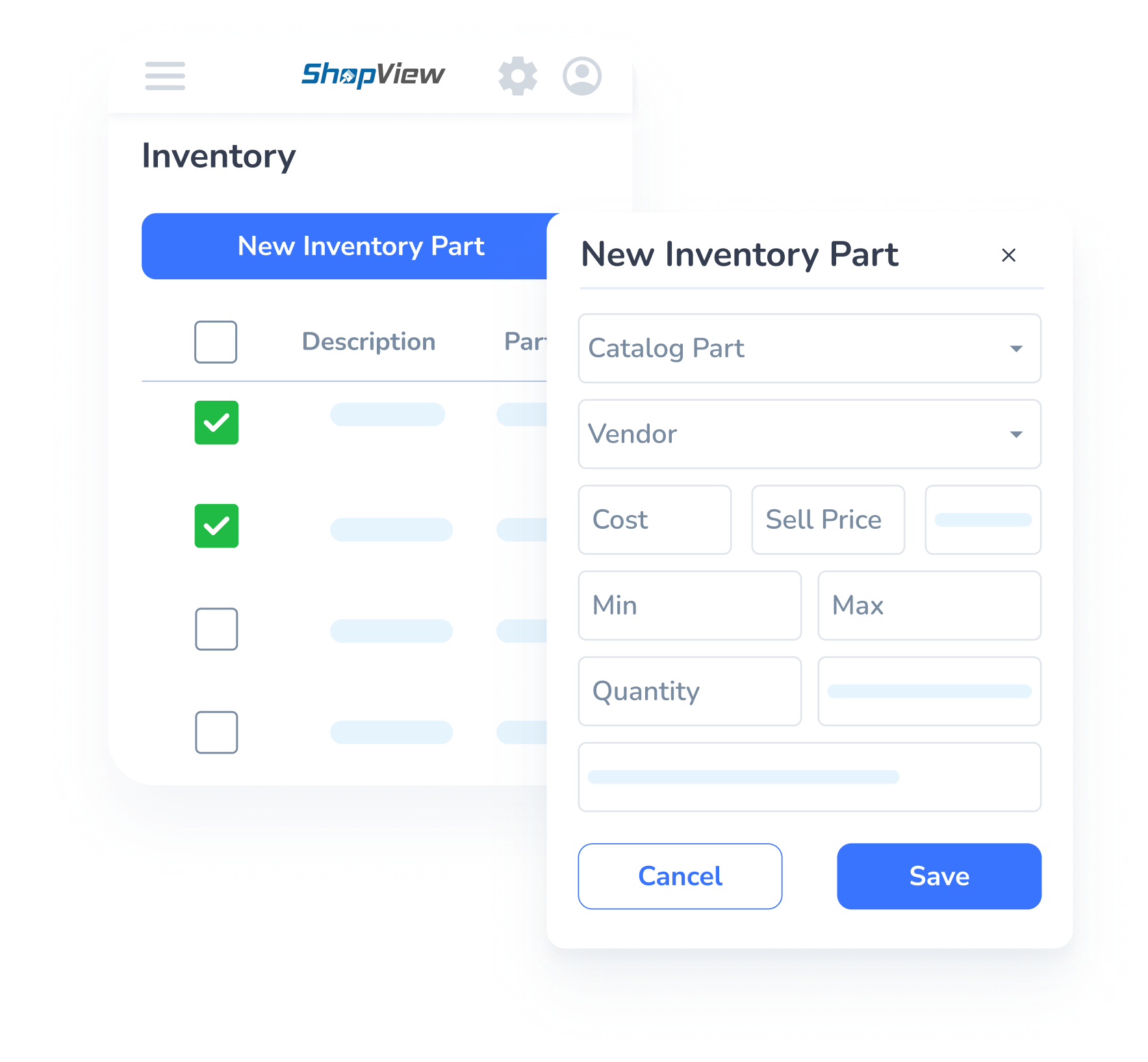

ShopView's repair shop inventory management software keeps your inventory lean, accurate, and ready for every job that rolls in - whether you're running a diesel, fleet, or heavy-duty repair shop.

Stay Accurate with Cycle Counts

Keep inventory accurate year-round without shutting down operations. ShopView lets you schedule targeted cycle counts, catch discrepancies early, and maintain real-time accuracy. Perfect for shops balancing multiple bays or locations.

Inventory Control Without the Headaches

Stop guessing what's on the shelf or over-ordering out of fear. ShopView's diesel inventory management system gives you total visibility - and saves hours every week.

Real-Time Inventory Levels

Always know what you have, what you need, and what's on the way.

Organized Parts Catalog

Sort and categorize by item, vendor, or job - and view full purchase history.

Automatic Purchase Order Generation

ShopView auto-generates POs, so you focus on repairs, not paperwork.

Multi-Location, One View

Whether managing one bay or five shops, ShopView keeps your parts system centralized, connected, and synced.

Cross-Location Visibility

Track parts usage and availability across all shop locations in one dashboard.

Transfer & Reallocate Parts

Move stock between shops in seconds - avoid delays, stockouts, or overordering.

Consolidated Reporting

View inventory levels, usage trends, and cost reports in one place.

Explore More Tools from ShopView

Continue your product tour, dive deeper into each feature

Work Orders

Build and manage jobs fast - fully detailed and ready in under 2 minutes.

Technician Time Clock

Track time by job, bay, or task for precise billing and reports.

Estimates & Invoices

Create accurate estimates and convert to invoices instantly.

Scheduling

Drag and drop to assign jobs, balance workloads, and stay on track.

Reporting & Analytics

View trends, tech stats, and job margins to grow your business.

Built By Shop Owners Who've Been Through It

We've run the same parts rooms you're running. And we built ShopView to eliminate the mess. No more spreadsheets, no more surprises. Just clear, easy, real-time inventory management that makes sense for your shop.

Learn More About Our Revolutionary SoftwareWhy Choose ShopView?

ShopView gets you out of the day-to-day weeds of running your shop by simplifying all your time-consuming admin, management and billing. It dramatically increases the output of your team, without making a single new hire.

Available on all devices

Simple to set up and use on computers, smartphones and tablets.

Seamless integration

Connects with accounting and business systems you already use.

Comprehensive support

From onboarding to ongoing support, reach out anytime for help within 12 hours.

The Ultimate Guide to Parts & Inventory Management for Heavy-Duty Shops

Why Inventory Management Is Critical

If you run a heavy-duty repair shop, you know that parts availability can make or break your business. A missing component delays jobs, upsets customers and erodes profits. Too many parts on the shelf ties up capital and increases carrying costs.

Manual inventory methods - Excel sheets, handwritten lists or a mental catalogue - may work when you're small, but they quickly become unsustainable as jobs multiply and your parts catalogue grows.

Inventory & parts management software solves these challenges by giving you a central platform to track parts, control stock levels and synchronize ordering across your business.

What Is Inventory Management Software?

Inventory management refers to the process of ordering, storing, using and selling a company's inventory. Parts management software digitizes these tasks: it provides a centralized system to catalogue every part, monitor stock levels across multiple locations, automate reordering and integrate with other shop systems.

Modern inventory software automates data entry through barcode and RFID scanning, generates real-time stock updates and alerts managers when levels fall below predetermined thresholds.

Heavy-duty and diesel repair shops handle thousands of parts - filters, gaskets, brake pads, hoses, specialized bolts - and these parts vary by engine make and model. Real-time tracking ensures technicians always know where parts are.

Common Pain Points and Solutions

Lost Time - When technicians must manually check stock, they lose billable hours. Barcode or RFID scanning updates part locations instantly.

Shrinkage - Parts can go missing through misplacement or theft. Automated systems log every scan and movement for accountability.

Overstocking - Ordering without visibility leads to excess stock tying up capital. Automated reorders based on thresholds maintain optimal stock.

Stockouts - Nothing hurts customer satisfaction more than missing a simple part. The system triggers alerts or automatic reorders when parts run low.

Key Features of Robust Systems

- Multi-Location Tracking - Know where parts are across multiple bays, warehouses or service trucks

- Barcode & RFID Scanning - Update stock counts instantly with minimal human error

- Automated Reordering - Trigger orders when stock falls below thresholds

- Demand Forecasting - Predict future stock needs using historical data

- Multi-User Access - Team members work simultaneously with real-time updates

- Work Order Integration - Parts automatically associated with specific jobs

- Reporting & Dashboards - Metrics like turnover rates, stock valuation, shrinkage

Benefits and ROI

Accuracy - Automated systems eliminate stock-level miscalculations through continuous updates.

Time Savings - Technicians spend less time searching for parts and more time on repairs.

Visibility - Real-time visibility into parts inventory across multiple locations.

Cost Reduction - Reduce overstocking by triggering reorders only when necessary.

Scalability - Systems that grow with your business - more bays, technicians, locations.

Customer Satisfaction - Repairs completed on time with parts always available.

Use Cases for Different Teams

Heavy-Duty Truck & Diesel Shops - Manage variety and cost of components across multiple engine brands. Integrate with work-order software for automatic job association.

Fleet Operations - Schedule preventive maintenance based on mileage or engine hours while ensuring parts are on hand.

Construction Equipment - Track specialized parts and attachments with RFID tags for large components.

Dealerships - Synchronize retail and service inventory with automatic stock count updates.

Pros and Cons

Advantages

- Automation streamlines the entire inventory lifecycle

- Accuracy from barcode/RFID scanning eliminates errors

- Real-time visibility across multiple locations

- Cost savings through automatic reorders

- Data analytics support strategic purchasing

- Scalability to handle growth

Drawbacks

- Learning curve for implementing new software

- Upfront costs for subscriptions and hardware

- Dependence on technology and connectivity

- Data migration from legacy systems requires planning

How to Choose the Best System

- Clarify objectives - Better visibility? Reduced stockouts? Lower carrying costs?

- Evaluate ease of use - Intuitive for technicians, service managers and parts personnel

- Ensure feature fit - Multi-location tracking, scanning, automatic reorders, forecasting

- Check integration - Seamlessly integrate with work orders, invoicing and scheduling

- Compare pricing - Per user, location or inventory volume pricing models

- Evaluate support - Onboarding assistance, training resources, response times

Implementation Tips

- Planning - Document current processes and identify who will use the system

- Data Migration - Import cleaned data, set up warehouses and locations, configure roles

- Training - Role-specific training for parts staff, technicians and managers

- Monitoring - Track adoption using reporting tools, monitor key metrics

Future Trends

Artificial intelligence (AI) and predictive analytics are enabling more accurate forecasting and automating reorder processes.

Integration with Internet of Things (IoT) devices allows parts and equipment to send real-time data on usage and condition, triggering maintenance and reordering without human intervention.

Sustainability initiatives are also influencing inventory practices: businesses are optimizing packaging and delivery routes to reduce waste and emissions.

Conclusion

Inventory and parts management is the backbone of every heavy-duty repair operation. Manual methods expose shops to errors, delays and unnecessary costs.

By adopting a comprehensive inventory management system with features like multi-location tracking, barcode/RFID scanning, automated reorders, forecasting and integration with other shop software, you can eliminate guesswork, reduce waste and empower your team to focus on what matters: repairing equipment and serving customers.

Ready to Increase Your Shop's Revenue by 20%+?

Join thousands of heavy-duty repair shops that trust ShopView to manage their operations profitably.