Technician Time Clock That Boosts Billable Hours

Never miss another minute of tech time. Increase your tech billable hours by up to 2 hours per day, per tech!

Simple for Techs. Powerful for Owners.

ShopView's time clock is built right into your fleet maintenance software - no extra apps, no confusing steps.

Clock In, Clock Out - Automatically

ShopView eliminates time tracking errors and streamlines technician workflows by embedding the time clock directly into the tools your techs already use.

Job-Based Time Tracking

Time is logged per job - so every minute is accounted for.

Start/Stop Simplicity

Techs tap once to clock in and again to clock into the next job. That's it.

No More Missed Time

Time data syncs directly into work orders and invoices, so nothing slips through the cracks.

Maximize Billable Hours, Minimize Admin

Manual time sheets? Gone. ShopView's digital technician time clock ensures you're capturing every billable second.

Instant Payroll Reports

View total hours, jobs completed, and idle time by technician or team.

More Billable Time

Shops using ShopView's time clock average 20% more billable technician time.

Real-Time Visibility for Managers

No more guessing who's working on what. With ShopView, you get a live look at your entire team's activity.

Live Activity View

See which techs are clocked in, what they're working on, and what they are doing next.

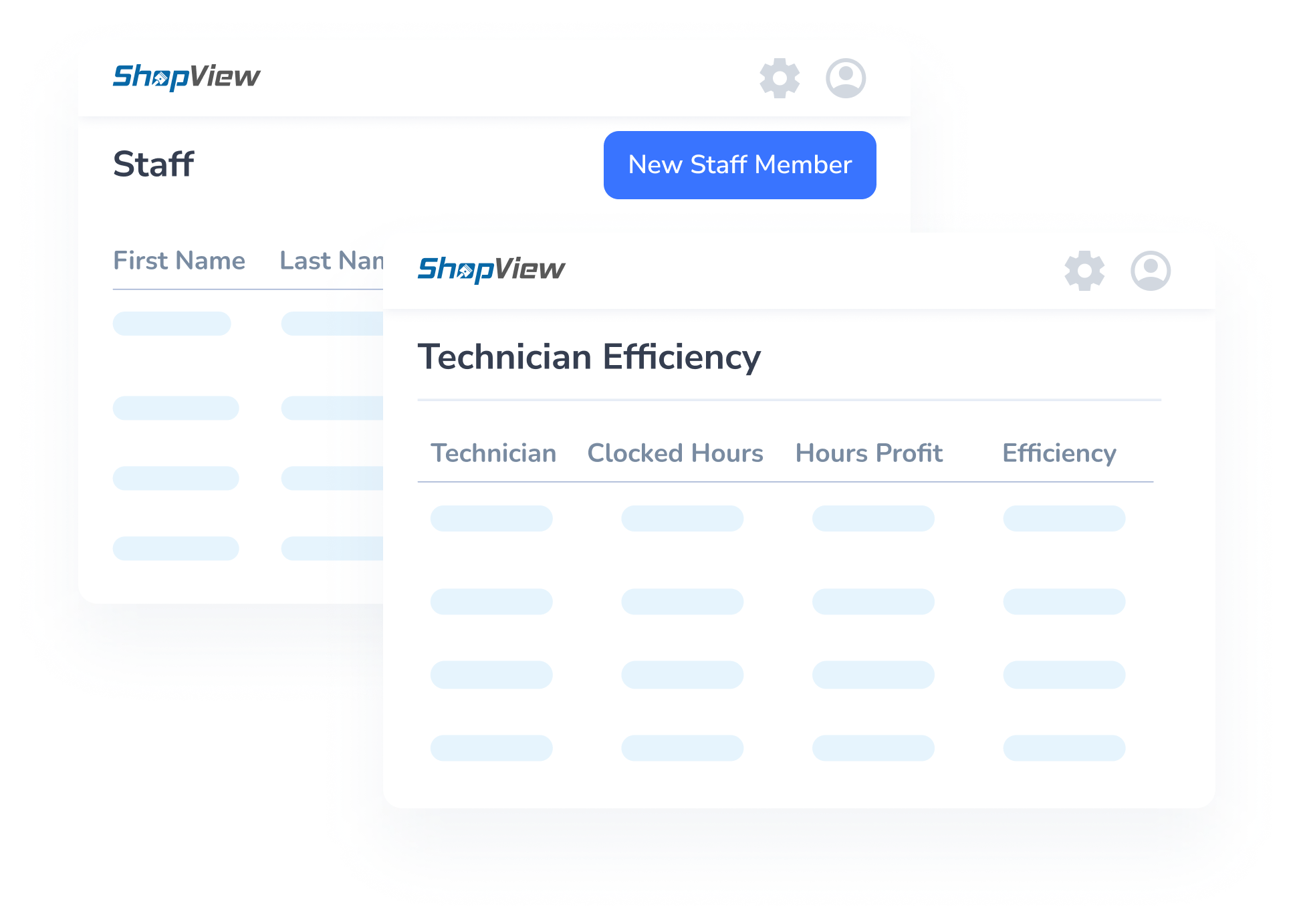

Track Efficiency

Compare billed hours to actual job time to spot inefficiencies, boost output, and coach your team.

Audit-Ready Logs

Every punch is recorded and stored for transparency and reporting.

Explore More Tools from ShopView

Continue your product tour, dive deeper into each feature

Work Orders

Build and manage jobs fast - fully detailed and ready in under 2 minutes.

Parts Inventory

Monitor stock levels in real time and manage usage with ease.

Estimates & Invoices

Create accurate estimates and convert to invoices instantly.

Scheduling

Drag and drop to assign jobs, balance workloads, and stay on track.

Reporting & Analytics

View trends, tech stats, and job margins to grow your business.

Built by Shop Owners Who Know the Cost of Missed Time

We've been in your boots. As heavy-duty shop owners, we know how much billable time slips through the cracks when you're using paper timesheets or generic software. That's why we built ShopView's time clock to be fast, accurate, and built for the way real shops work.

Learn More About Our Revolutionary SoftwareWhy Choose ShopView?

ShopView gets you out of the day-to-day weeds of running your shop by simplifying all your time-consuming admin, management and billing. It dramatically increases the output of your team, without making a single new hire.

Available on All Devices

ShopView is simple to set up and use on computers, smartphones and tablets.

Seamless Integration

ShopView connects with the accounting and business systems you already use.

Comprehensive Support

From onboarding to ongoing support, just reach out to our team any time you need support.

The Ultimate Guide to Technician Time Tracking Software for Heavy-Duty Repair Shops

Introduction

Time is the most valuable resource in a heavy-duty repair shop. Every minute technicians spend searching for parts, waiting for instructions or manually filling out timesheets is lost billable time.

Poor time tracking leads to lost hours, payroll headaches, customer misquotes and team tension. Modern technician time tracking software solves these problems by automating clock-ins and clock-outs, capturing work hours accurately, and integrating with scheduling, work-order and payroll systems.

Why Time Tracking Matters

Labor costs represent the largest expense after parts in most repair shops. Without accurate tracking, shops either undercharge customers or overpay technicians.

Manual timesheets rely on memory and guesswork; they're error-prone and susceptible to time theft. Heavy-duty repairs involve multiple complex steps - diagnostics, tear-down, machining, parts sourcing, assembly and testing. Without granular time tracking, identifying inefficiencies becomes impossible.

Fleet managers and equipment owners demand transparency, wanting to understand why repairs cost specific amounts and took specific durations.

What Is Technician Time Tracking?

Technician time tracking is the systematic process of recording the time technicians spend on tasks, projects or jobs. Instead of relying on memory or paper time cards, technicians use mobile apps, digital time clocks or geofencing to log their hours.

A comprehensive time tracking system captures:

- Start and end times for each job or task

- Breaks, travel time and idle time

- Specific tasks performed (diagnostics, parts ordering, installation)

- Technician notes, photos or signatures

- GPS location or geofence verification

Key Features to Look For

- Real-Time Tracking - Up-to-date visibility into technician locations and activities

- Automated Time Logs - Streamlined work hour recording reducing manual entry errors

- Integration - Connect with project management, payroll and accounting

- Comprehensive Reporting - Transform raw data into actionable insights

- Customization - Set work schedules, break policies, overtime rules

- Mobile Access - Log hours from smartphones or tablets

- GPS and Geofencing - Verify technician locations and automate clocking

- Biometric Verification - Prevent buddy punching with fingerprint or facial recognition

Benefits and ROI

Improved Accountability - Automated logs reduce errors and provide verifiable work records.

Streamlined Operations - Reduce time spent chasing timesheets; integrate with payroll and accounting.

Enhanced Payroll Accuracy - Fair, precise compensation eliminating guesswork.

Billing Accuracy - Visibility into billable versus non-billable hours improves profitability.

Data-Driven Decisions - Identify high performers, bottlenecks and inefficiencies.

Compliance - Accurate records demonstrate compliance with labor laws.

Use Cases for Heavy-Duty Shops

Heavy-Duty Repair Shops - Assign labor hours to specific work orders, ensuring correct billing and revealing which repair types yield best margins.

Fleet Maintenance - Track hours per unit to ensure warranty compliance and accurate billing.

Mobile & Field Service - GPS and geofencing automatically clock in/out based on job site arrival.

Multi-Location Operations - Centralized time tracking for consistent payroll and reporting across sites.

Contracted Labor - Log hours for both employees and contractors with clear documentation.

Pros and Cons

Pros

- Accuracy and accountability through automated logs

- Efficiency gains - less time on timesheets

- Fair compensation with correct overtime calculations

- Data insights highlighting productivity trends

- Improved customer billing with accurate invoices

- Compliance with labor laws

Cons

- Employee resistance if perceived as intrusive

- Implementation challenges requiring training

- Upfront costs for hardware and subscriptions

- Data privacy concerns from location tracking

- Technology dependence for system availability

How to Choose the Right Solution

- Clarify your goals - Reduce overtime? Improve billing accuracy? Prevent time theft?

- Assess compatibility - Map how work orders are created and how time data flows to payroll

- Evaluate tracking methods - Mobile apps, web clocks, facial recognition tablets

- Ensure customization - Configure break policies, overtime rules, pay rates

- Prioritize robust reporting - Exportable data and visual dashboards

- Choose scalable solutions - Support more technicians and locations

- Compare costs and ROI - Consider per-user or subscription pricing

Implementation Best Practices

- Choose appropriate tools - Assess workforce size, job types and tech proficiency

- Train your team - Provide step-by-step guides and videos

- Establish clear policies - Outline when to clock in/out and how to track breaks

- Integrate with payroll - Ensure seamless data transfer

- Monitor and review - Identify patterns and follow up with coaching

- Maintain open communication - Address concerns promptly

Conclusion and Next Steps

Accurate time tracking is essential for heavy-duty repair shops managing complex jobs, mobile crews and tight margins. Precise data enables labor cost control, accurate customer billing and team productivity improvement.

Manual timesheets cannot keep pace with modern shop demands. Modern technician time tracking software automates the process, ensuring real-time visibility, seamless integration with work orders, payroll and scheduling, and detailed reporting.

Investing in robust systems improves accountability, streamlines operations, enhances payroll and billing accuracy, provides data-driven insights, supports work-life balance and ensures labor law compliance.

Ready to Increase Your Shop's Revenue by 20%+?

Join thousands of heavy-duty repair shops that trust ShopView to manage their operations profitably.