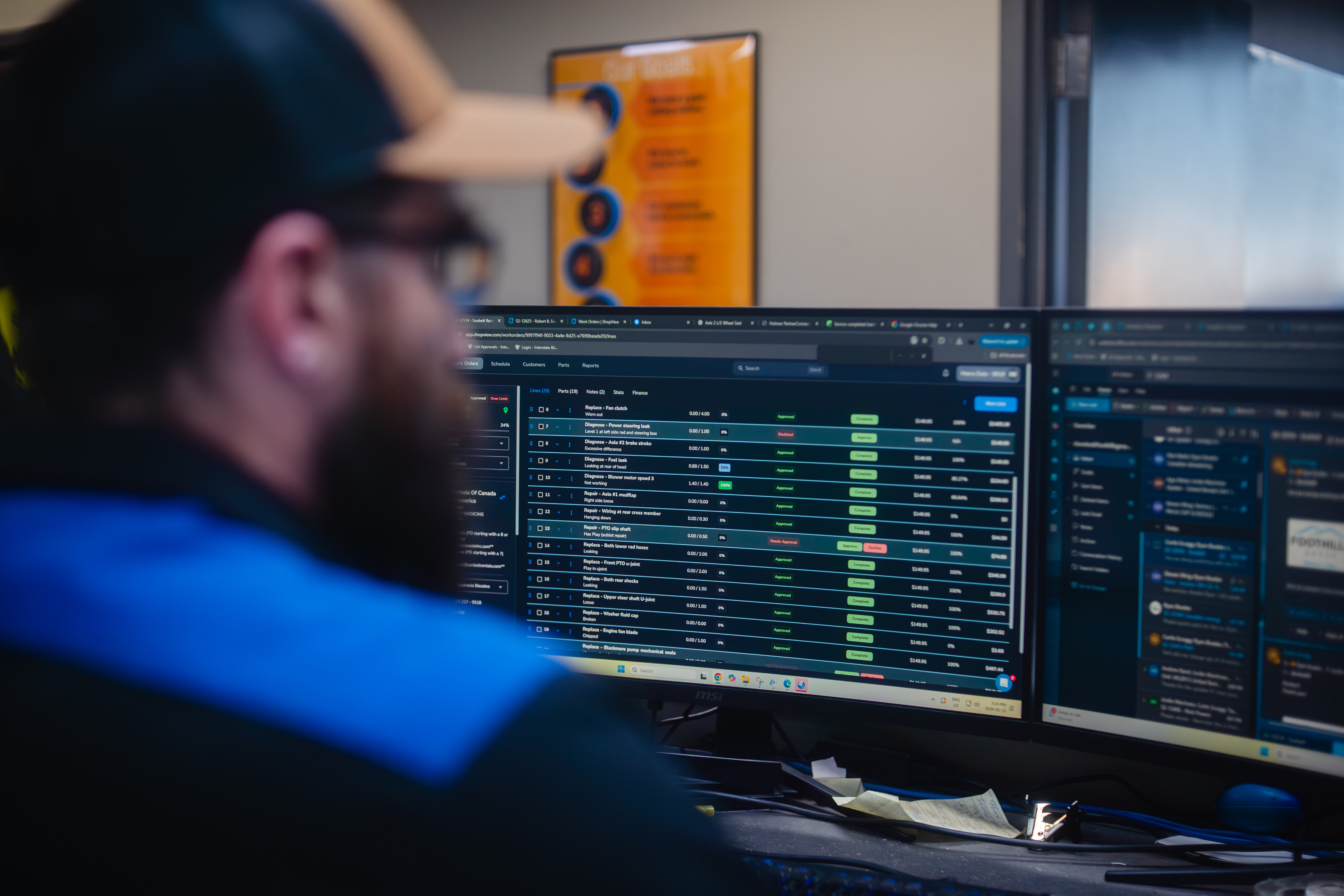

Work Orders That Get Jobs Done Faster - Built for Heavy-Duty Repair Shops

Create and manage service work orders in under 2 minutes with ShopView. It's the fastest way to keep your heavy-duty repair shop running smooth, efficient, and profitable - without the stress.

Fastest Work Order Build-Out in the Industry

Time is money. That's why ShopView gives you the tools to build fully detailed work orders or estimates in less than 2 minutes - start to finish. Whether you're writing up a new repair, reviewing past service history, or converting an estimate into an invoice, ShopView's repair shop work order software gets it done faster.

Simplified Service Order Management

From intake to invoice, ShopView simplifies every step of the service process - no bottlenecks, no delays. Just one straight line from job start to payment.

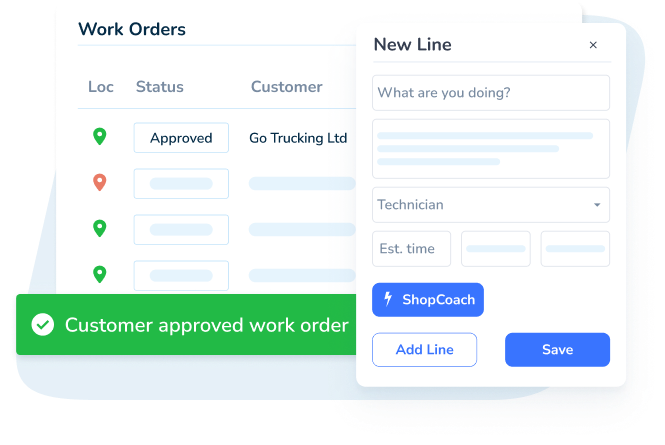

Effortless Job Creation

Instantly assign techs, add labor, parts, and customer notes - all from one place.

Clear Communication

Eliminate back-and-forth with smart fields, service status tracking, and automatic updates your whole team can see.

Instant Visibility

Get real-time insights into job progress, technician time, and work order status across every bay.

Collaborative Workflows for Your Whole Team

Work orders shouldn't live on sticky notes. ShopView connects your entire team with an intuitive, centralized system.

Technician Friendly Workflow

Techs can clock in, update tasks, add photos, and complete jobs - right from their tablet or phone.

Zero-Slip Time Clock

Ensure accurate time tracking with clock-in/out automation tied directly to each work order. No more guessing where your labor hours went.

Live Job Progress

Managers see exactly what's happening - without chasing people down for updates.

From Work Order to Invoice in Seconds

Convert completed work orders into professional invoices with just a few clicks. ShopView captures all labor, parts, shop supplies, and tax data - so you get paid faster, with zero missed revenue.

One-Click Conversion

Finalize and send invoices to customers directly from the work order.

Accurate Billing

Pull in technician time, part costs, and margins automatically for precise, profitable invoicing.

Approval Tracking Made Easy

See status at a glance. No paperwork. No guesswork. Just clean billing.

Explore More Tools from ShopView

Continue your product tour, dive deeper into each feature

Technician Time Clock

Track time by job, bay, or task for precise billing and reports.

Reporting & Analytics

View trends, tech stats, and job margins to grow your business.

Parts Inventory

Monitor stock levels in real time and manage usage with ease.

Estimates & Invoices

Create accurate estimates and convert to invoices instantly.

Scheduling

Drag and drop to assign jobs, balance workloads, and stay on track.

Built By Heavy Duty Shop Owners Who Know the Grind

We didn't just imagine a better work order system - we built the one we wish we had in our own shops. After 20+ years of running repair shops, we knew there had to be a faster, simpler way. ShopView is that way. It's everything you need, nothing you don't - built by people who've been there.

Learn More About Our Revolutionary SoftwareWhy Choose ShopView?

ShopView gets you out of the day-to-day weeds of running your shop by simplifying all your time-consuming admin, management and billing. It dramatically increases the output of your team, without making a single new hire. When your shop runs more efficiently with ShopView, life's just better. There's more free time to spend doing what you want. Less stress. And fewer operational headaches. Better yet, ShopView is designed to pay for itself - many times over.

Available on All Devices

ShopView is simple to set up and use on computers, smartphones and tablets. Then all your shop information is stored in the cloud and automatically synced across all devices.

Seamless Integration

ShopView connects with the accounting and business systems you already use to connect all parts of your shop's operations and reduce administrative effort.

Comprehensive Support

From onboarding to ongoing support, just reach out to our team any time you need support and we'll be back in touch within 12 hours.

The Ultimate Guide to Work-Order Software for Heavy-Duty Repair Shops

Introduction

In a heavy-duty repair environment, time literally equals money. Every hour a truck sits idle in a bay is an hour you can't bill a customer or send equipment back on the road. Miscommunication about what needs to be done leads to rework, and paper-based processes slow down everything from scheduling to invoicing.

A purpose-built work-order management system solves these problems by giving you a single place to create, assign, track and complete every job from start to finish.

What Is Work-Order Management Software?

At its core, work-order management software is a digital platform that centralizes all the information and tasks associated with service jobs. Instead of juggling paper tickets, spreadsheets or standalone applications, teams can initiate, assign and track work orders from one interface.

A well-designed system automates the lifecycle: as soon as a service request comes in, it can be logged, validated and dispatched to the appropriate technician. Throughout the process, managers and technicians have real-time visibility into job status, notes, parts used and time spent.

Because everything is recorded digitally, tasks are searchable, audit trails are complete and data can be analyzed for continuous improvement. The best work-order systems go beyond basic ticketing. They integrate with inventory and asset management tools, automatically update maintenance history and provide mobile access so technicians can update their progress on the go.

How It Differs from Traditional Methods

Many shops still rely on manual processes: handwritten work orders, whiteboard schedules or generic project-management apps. While these methods can work for small teams, they quickly break down as job volume increases. Manual data entry leads to errors, illegible notes make communication difficult, and there is no real-time overview of what's happening on the floor.

In contrast, a work-order management system digitizes every step. Tasks are searchable, statuses update instantly, and everyone works from the same source of truth. This transparency eliminates bottlenecks and allows managers to allocate resources more effectively.

Why Your Shop Needs Work-Order Software

Facility managers and service contractors juggle numerous tasks each day - from routine preventive maintenance to emergency breakdowns. Without an organized system, important jobs fall through the cracks, work orders are assigned to the wrong technician, and communication happens haphazardly through phone calls or sticky notes.

Pain Points in Heavy-Duty Repair

Heavy-duty repair shops face unique challenges. Trucks and equipment are often large and complex, requiring specialized tools and expertise. Parts may need to be ordered from multiple suppliers, and repairs can span multiple shifts or locations. Without a central system to track every step, it's easy to lose track of who is responsible for what and whether a job is still on schedule.

Business Benefits and ROI

Implementing a work-order management system delivers tangible returns. By automating scheduling, dispatching and status updates, your shop spends less time on manual admin and more time turning wrenches. Centralized work-order data helps reduce downtime and ensures that critical assets are serviced promptly.

Customers also see the benefits. With accurate time estimates and clear communication, they have more confidence in your shop's ability to complete repairs on schedule. And when combined with automated invoicing, the system ensures that every billable hour and part is captured, increasing revenue without increasing headcount.

Key Features to Look For

Not all work-order systems are created equal. When evaluating software, consider the following features:

- Task Scheduling and Dispatch - Assign jobs based on technician availability, skillset and location with drag-and-drop calendars.

- Real-Time Tracking - Live updates as technicians begin, pause or complete tasks, enhancing communication.

- Inventory Integration - Know whether parts are in stock and where they're located.

- Mobile Accessibility - Technicians can receive assignments and update statuses from anywhere.

- Customizable Workflows - Define custom templates, required fields and approval steps.

- Reporting and Dashboards - Metrics like job completion times, labor utilization and parts usage.

- Integration with Other Tools - Connect with invoicing, scheduling, inventory, CRM and accounting systems.

Benefits of Work-Order Software

Increased Efficiency and Productivity - When technicians know exactly which job to work on, where to find parts and how to report issues, they waste less time and complete more tasks.

Reduced Downtime and Maintenance Costs - Proactive scheduling and real-time updates reduce equipment downtime. Integrated asset histories allow you to see patterns in breakdowns and schedule preventive maintenance accordingly.

Better Communication and Accountability - Work-order software provides a central communication hub. Technicians receive clear instructions, managers monitor progress, and customers get status updates.

Improved Customer Satisfaction - Clear communication, accurate estimates and on-time delivery build trust with your customers.

Increased Revenue - Capturing every billable hour and part eliminates revenue leakage. Automated invoicing ensures that completed work orders seamlessly feed into billing.

Work-Order Software for Different Teams

While all work-order systems share common features, different industries and team structures may have specific needs.

Heavy-Duty Repair Shops - Need detailed job templates, robust parts tracking and the ability to attach photos or diagnostic data to work orders.

Fleet Maintenance - Schedule recurring maintenance based on mileage or engine hours, track service histories and ensure regulatory compliance.

Construction and Facilities Management - Prioritize jobs based on safety or production impact and coordinate technicians across multiple job sites.

Pros and Cons

Pros

- Streamlined workflows with automated scheduling and dispatching

- Greater visibility with real-time tracking and dashboards

- Improved accuracy with digitized records

- Better data for decisions through reporting tools

- Seamless integration with inventory, billing and accounting

Cons

- Learning curve requiring training and change management

- Upfront subscription fees or licenses

- Dependence on technology and network connectivity

Despite these potential drawbacks, the long-term benefits of digitizing your work-order processes usually outweigh the initial challenges.

Industry Adoption and Trends

Work-order systems have evolved significantly. Early solutions were expensive programs requiring on-premise servers. Cloud computing changed that - modern platforms are scalable, affordable and accessible to businesses of all sizes.

However, more than 75 percent of companies still use spreadsheets, paper or nothing at all to manage maintenance. This gap represents a massive opportunity: adopting a digital system can put your shop ahead of the majority of the industry.

Industry analysts predict continued growth in the computerized maintenance management system (CMMS) market as companies recognize the need to streamline operations and leverage data for strategic decision-making.

Compliance, Safety & Quality Control

A digital work-order platform helps you meet regulatory obligations by embedding compliance into daily workflows. Standard operating procedures and checklists stored in the system ensure technicians follow proper steps and document their work.

When auditors or inspectors request proof, you can provide time-stamped records, photos and digital signatures at the click of a button. The system's audit trail also simplifies warranty claims and service history retrieval.

Safety inspections can be codified into mandatory fields, ensuring that no one forgets to perform a lock-out/tag-out procedure or record a safety check before starting a repair.

Overcoming Implementation Challenges

Adopting a new system always comes with challenges:

- Resistance to change - Involve staff early in the selection process and demonstrate how the software reduces repetitive tasks.

- Training and onboarding - Provide role-specific training sessions and appoint "champions" within your team.

- Budget constraints - Build a business case that quantifies the ROI from reduced downtime and increased billable hours.

- Connectivity issues - Choose a platform with offline functionality so technicians can continue working without losing data.

- Data migration - Work with your vendor to map existing data and import historical records.

The Future of Work-Order Management

Work-order software continues to evolve with emerging trends:

- AI and Predictive Analytics - Systems will increasingly predict failures before they happen by analyzing historical data and sensor readings.

- Digital Twins - Virtual replicas of equipment allow technicians to simulate repairs and train without touching the real machine.

- Expanded IoT Connectivity - Integration with telematics, AR devices and wearables will provide unprecedented insight.

- Greater Customer Transparency - Client portals where fleet operators can see job status and approve estimates in real time.

- Sustainability - Future systems will track environmental metrics and help shops meet sustainability goals.

How to Choose the Best Software

Key considerations when selecting work-order software:

- Define your goals - Clarify objectives to prioritize features.

- Assess usability - Request a demo to see how it fits into your workflow.

- Consider customization and scalability - Look for a system that can grow with your business.

- Check integrations - Ensure it connects to your existing tools.

- Evaluate pricing - Calculate potential ROI from reduced downtime and increased billable hours.

- Ask about support and training - Look for vendors with industry expertise.

Conclusion and Next Steps

Work-order management software is no longer a luxury; it's the backbone of an efficient, data-driven repair operation. By replacing manual processes with a digital system, you gain visibility into every job, streamline communication and unlock insights that help you allocate resources wisely.

Modern platforms can dramatically improve operations, decrease downtime, automate complex workflows, and simplify preventive maintenance. With features like real-time collaboration, mobile access, preventive maintenance scheduling, IoT integration and compliance tracking, today's systems are far more than digital ticketing tools.

Whether you manage a heavy-duty truck shop, a fleet maintenance operation or a construction yard, now is the time to modernize your work-order processes.

Ready to Increase Your Shop's Revenue by 20%+?

Join thousands of heavy-duty repair shops that trust ShopView to manage their operations profitably.