Reporting & Analytics That Drive More Profit

ShopView's repair shop reporting software turns your day-to-day operations into actionable insights - so you can make smarter decisions, faster.

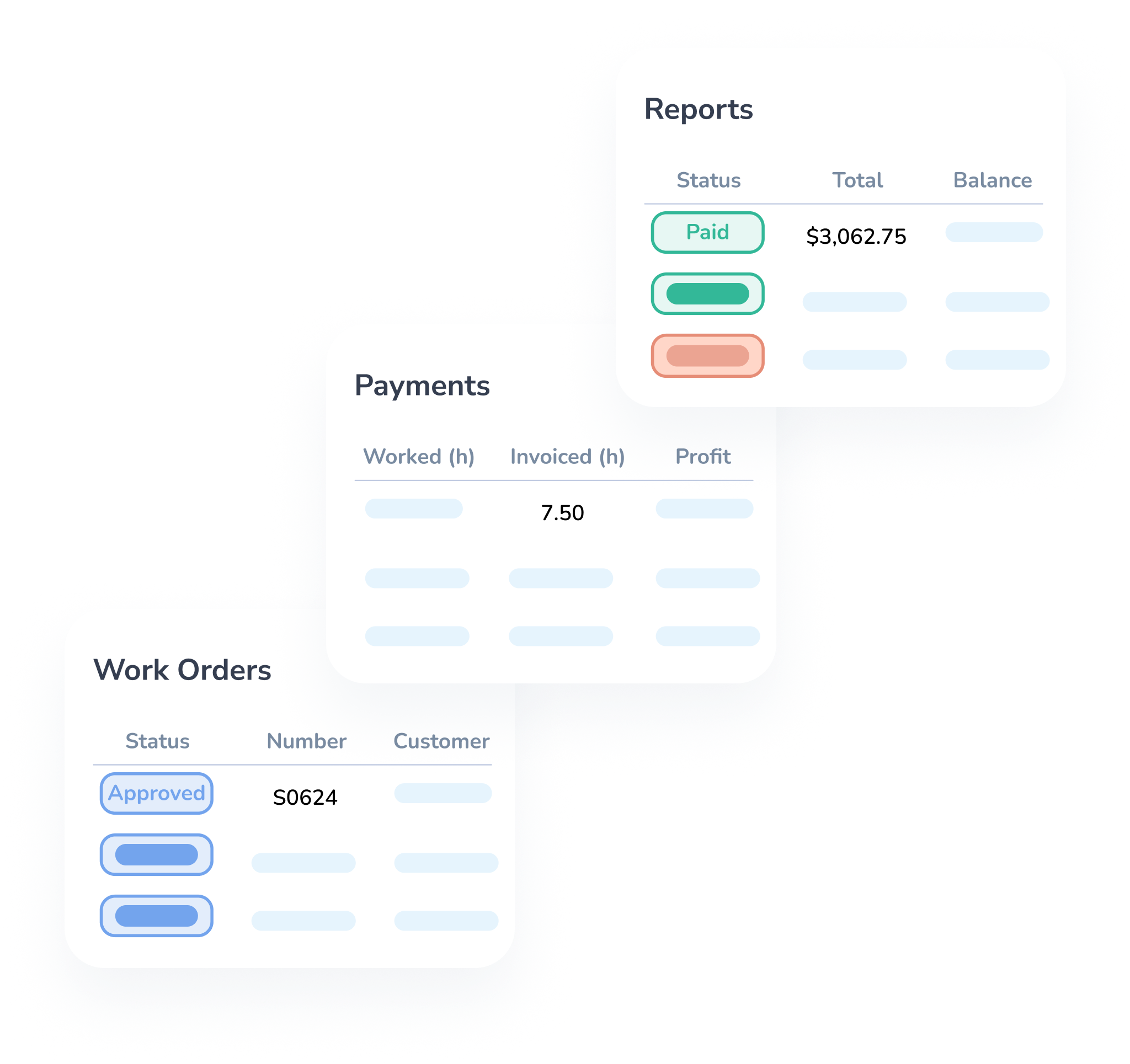

Total Visibility Into Shop Performance

You can't improve what you can't see. ShopView gives you instant access to the numbers that actually matter - technician output, labor efficiency, inventory turnover, revenue trends, and more.

Live Revenue Reporting

See how your shop is performing by day, week, or month - and spot patterns at a glance.

Technician Efficiency

Track actual hours vs. billed hours to uncover missed profit and underutilized time.

Service Advisor Performance

Easily identify your top-performing advisor to drive higher profits.

Know Exactly Where Time and Money Are Going

Whether you're managing one shop or several, ShopView's technician and maintenance software helps you stay in control of every corner of your business.

Labor Margin Insights

Measure labor profitability down to the task - by job, by service advisor, or by technician.

Parts Margin Insights

Measure margins by job and ensure you're hitting your targets - so your parts department stays profitable.

Technician Performance

Track tech times accurately. Identify unbilled hours and optimize your heavy duty work order billing process.

Smarter Decisions. Less Guesswork.

You don't need to be a numbers person. ShopView's repair shop analytics tools do the heavy lifting - so you spend less time digging through spreadsheets and more time growing your business.

Explore More Tools from ShopView

Continue your product tour, dive deeper into each feature

Work Orders

Build and manage jobs fast - fully detailed and ready in under 2 minutes.

Technician Time Clock

Track time by job, bay, or task for precise billing and reports.

Parts Inventory

Monitor stock levels in real time and manage usage with ease.

Estimates & Invoices

Create accurate estimates and convert to invoices instantly.

Scheduling

Drag and drop to assign jobs, balance workloads, and stay on track.

Built by Shop Owners for Insane Cash Flow

We built ShopView because sloppy data was killing our profits. We demanded clear metrics to make big money. Now, it's your turn to cash in with your shop. Our wallets are stuffed - let us show you how to make serious bucks!

Learn More About Our Revolutionary SoftwareWhy Choose ShopView?

ShopView gets you out of the day-to-day weeds of running your shop by simplifying all your time-consuming admin, management and billing. It dramatically increases the output of your team, without making a single new hire.

Available on all devices

Simple to set up and use on computers, smartphones and tablets.

Seamless integration

Connects with accounting and business systems you already use.

Comprehensive support

From onboarding to ongoing support, reach out anytime for help within 12 hours.

Ultimate Guide to Reporting & Analytics for Heavy-Duty Repair Shops

Introduction

Running a heavy-duty repair shop requires understanding operations in real time. Without insight into work order flow, technician performance, downtime patterns, and parts utilization, decision-making becomes difficult.

Reports and dashboards convert raw operational data into clarity, revealing which processes are efficient and which need improvement.

What Are Reporting Dashboards?

A reporting dashboard is a visual interface displaying metrics from various data sources consolidated into a single view. For repair shops, data sources include work orders, technician time logs, parts inventory, invoices, and maintenance schedules.

Dashboards present information through charts, graphs, and scorecards for quick trend interpretation. Unlike static reports generated at fixed intervals, dashboards update continuously, providing always-on visibility.

Why Reporting & Analytics Matter

Data-driven decisions outperform instinct-based approaches. Dashboards centralize essential KPIs and enable visual comparisons across datasets, helping identify trends and monitor performance against benchmarks.

Real-time dashboards create shared visibility across teams, improving alignment and communication. They flag anomalies early, enabling proactive intervention before minor issues escalate.

CMMS reporting tools can reduce unplanned downtime by up to 40% and mean time to repair (MTTR) by 20% within the first 24 months.

Key Features of Reporting Tools

- Comprehensive Maintenance Reporting - Equipment status, repair history, maintenance activities

- Real-Time Dashboards - Monitor KPIs including repair times and technician utilization

- Actionable Alerts - Flag metrics outside acceptable ranges

- Cost & Operations Dashboards - Break down expenses by feature, location, or time

- Team Performance Tracking - Individual and team efficiency metrics

- Customization & Drill-Down - Adjust metrics, filters, and visual formats

- Cross-Module Integration - Work orders, inventory, time tracking, invoicing

- AI & Predictive Analytics - Forecast failures and optimize scheduling

Types of Dashboards and Metrics

Analytical Dashboards - Deep exploration of data and trends for detailed investigation.

Strategic Dashboards - Long-term goals and high-level KPIs for executive decision-making.

Operational Dashboards - Real-time monitoring of day-to-day activities.

Tactical Dashboards - Departmental performance metrics.

Key metrics to track: work order turnaround times, technician utilization, parts usage, labor costs vs billable hours, equipment availability, revenue trends, and preventive maintenance compliance.

Benefits and ROI

Dashboards centralize data and reveal trends through side-by-side metric comparison. Shared dashboards ensure teams coordinate from identical insight sets.

By flagging anomalies early, dashboards enable intervention before issues escalate. CMMS reporting tools centralize operational data, facilitating better workforce planning.

Asset-level reports reveal maintenance history and total cost of ownership, supporting data-driven decisions about equipment repair versus replacement.

Pros and Cons

Advantages

- Consolidate multiple data sources into single source of truth

- Real-time updates provide immediate information

- Visualizations make trend identification easier

- Shared dashboards promote collaboration

- Flag anomalies for proactive intervention

Disadvantages

- High-level views may lack deep analysis

- Too many metrics can create information overload

- Teams require training for correct interpretation

- Accuracy depends on quality underlying data

How to Choose the Best Solution

- Clarify goals - What metrics and questions should dashboards answer?

- Evaluate ease of use - Intuitive drag-and-drop interfaces

- Assess data integration - Seamless connection with work orders, inventory, time tracking

- Verify customization - Metric selection, filters, custom views

- Consider AI capabilities - Forecast failures and optimize maintenance

- Review vendor support - Training resources and industry expertise

- Analyze total cost - Integration, training, maintenance costs vs efficiency gains

Implementation Tips

- Start with core reports - Focus on key metrics like labor utilization and work order backlog

- Ensure data quality - Train on accurate data entry, regularly audit sources

- Create clear visualizations - Keep dashboards simple, avoid clutter

- Promote usage - Regular reviews where teams discuss results

- Make dashboards mobile-accessible - View updates on the shop floor

- Iterate continuously - Solicit feedback and refine based on needs

Future Trends

Artificial intelligence and machine learning will analyze sensor data and historical patterns to predict failures. Internet-connected sensors will feed real-time data on temperature, vibration, and fluid levels into dashboards.

Advanced visualization tools including augmented and virtual reality will make data more intuitive. As sustainability becomes priority, dashboards will monitor energy consumption, emissions, and waste.

Conclusion

Heavy-duty repair shops operate within complex environments where equipment uptime, technician efficiency, and parts availability drive profitability.

Dashboards and reports provide clarity by centralizing data, revealing trends, tracking performance against goals, and enabling timely intervention. They facilitate cohesive teamwork, empower informed decisions, and justify investments for long-term growth.

While dashboards have limitations and require quality data and training, advantages far outweigh challenges.

Ready to Increase Your Shop's Revenue by 20%+?

Join thousands of heavy-duty repair shops that trust ShopView to manage their operations profitably.