The holiday season is brutal for DVIR compliance. Skeleton crews, rushed dispatches, and the usual chaos of year-end operations create the perfect conditions for defects to slip through the cracks.

Under 49 CFR §396.11 driver inspection requirements, every safety defect noted on a DVIR must be repaired or certified "no repair needed" before the next driver takes the truck. Under 49 CFR §396.13 driver inspection guidance, the next driver is supposed to review the prior DVIR before moving the unit and be satisfied that the defect was handled.

DOT doesn't care if it was the week of Christmas or if your lead tech was in Mexico. Once the defect is written down, this is the chain they expect to see:

- Driver reports a defect

- Defect becomes a repair responsibility

- Repair is done or a "no repair needed" decision is recorded

- Someone signs for that decision

- The next driver can see it before taking the truck

- Records are still there when someone asks later

If any link in that chain breaks, that DVIR is considered unresolved, no matter how much work you actually did.

How the DVIR → Work Order Chain Is Supposed to Run

Forget software for a second. On paper, a clean DVIR workflow in an independent or mid-sized shop looks like this:

Driver documents the defect

End of shift or trip, the driver fills out the DVIR and notes anything that could affect safe operation: brakes, tires, lighting, steering, air leaks, coupling, suspension, frame issues.

DVIR lands where someone is responsible

That might be electronic or paper, but it has to land where a specific person is tasked with reviewing and acting on it.

Safety defects become work orders the same day

If the DVIR lists a safety-relevant defect, you create a repair order that:

- References the unit

- Mirrors the driver's description

- Ties back to the DVIR date

- Is treated as dispatch-blocking until resolved

Tech diagnoses and repairs

The technician pulls the work order, sees the DVIR complaint, and documents:

- What they found

- What they replaced/repaired

- Parts and labor

- How they verified the fix

Authorized person certifies the repair

Someone acting as the carrier's agent - shop owner, foreman, maintenance manager - signs that the defect was repaired or truly did not require repair.

Next driver reviews and acknowledges

Before operating the vehicle, the next driver reviews the prior DVIR and confirms the defect is no longer an open issue.

Records stick

DVIR, certification, and matching work order are retained and can be pulled quickly if DOT, a fleet customer, or an attorney asks for them.

That's the textbook version. Now, let's look at where holidays wreck it.

Where Holiday Staffing Breaks That Chain

DVIRs That Don't Turn into Work Orders

Your usual service writer is off. DVIRs show up in three different places - counter, inbox, and text. Nobody owns intake that day, so defects sit.

The driver wrote it up. You might even fix it "on the fly." But if there's no work order tied to that DVIR, you can't prove it.

"We'll Fix It After the Holidays"

You've got a DVIR that calls out a brake pull, low tread, a leak in an air bag, or a dead tail light. Bays are full, and someone decides it can run one more week.

If that defect affects safe operation, DOT's position is simple: that unit shouldn't have moved. "We were short-handed" doesn't move the needle.

Verbal Approvals Instead of Written Decisions

Driver: "Trailer ABS light is on."

Manager: "We've seen that before. You're fine."

If nobody signs the DVIR or notes a decision in the system, that conversation might as well not exist. Verbal approvals carry zero weight when someone reconstructs the record.

Repairs Done, but DVIR Never Signed

The tech fixes the issue. The truck goes back out. Nobody signs the DVIR or updates the eDVIR entry.

From an enforcement standpoint, that defect is still hanging open. DOT cares more about what the paperwork says than what people remember.

Skeleton Crews That Don't Know What's "Dispatch-Blocking"

Holiday coverage often means you've got the "B team" making calls. If they don't know which DVIR codes are legally "do not dispatch" versus "can schedule later," units roll that shouldn't.

Holiday-Proof DVIR → Work Order Workflow

You don't fix holiday DVIR risk with motivation. You fix it with a simple process that doesn't depend on specific people.

1. One Intake Channel for DVIRs

Make one rule:If it's a DVIR with a defect, it goes here.

That can be:

- A shared inbox

- A DVIR queue in your shop system

- A daily printed stack at the service counter

The point is: whoever is on duty knows where to look and knows that every defect in that pile must be turned into a job.

2. Same-Day Work Orders for Safety Defects

Any DVIR that mentions brakes, steering, tires, lighting, coupling, or major structural issues gets turned into a work order the same day it's received.

No "we'll get to it when it slows down."

If you can't at least open the job, your workflow isn't holiday-ready.

3. Flag Jobs That Legally Stop Dispatch

You can't trust memory when you're short-staffed. Build a simple red/yellow scheme into your process:

- Red: Legally cannot run until repaired/certified (brakes, tires, steering, lights, coupling)

- Yellow: Can be scheduled soon, doesn't stop dispatch

- Green: Cosmetic / advisory

Red jobs must be visible to anyone who might release a unit - on the schedule, status board, or even on a printed list. If a red defect is still open, that unit doesn't leave.

4. Make Techs Write for Future Auditors

In December, "checked OK" feels good enough.

In March, when someone is auditing a crash, it's useless.

Train techs that a DVIR-related repair note must explain:

- What the driver reported

- What they found

- What they did about it

- How they confirmed it's fixed

It's not just for DOT. It's also for the future you, standing there with someone asking, "Why did you let this truck go?"

5. Build Certification into Job Closure

Don't make DVIR sign-off a separate chore that someone "remembers later."

Fold it into your normal closure process:

- Job can't be closed until someone checks "DVIR defect resolved" and signs

- That signature then gets reflected on the DVIR or in the eDVIR system

The name doesn't have to be a master tech. It just has to be a responsible person who is willing to stand behind the decision.

6. Make It Easy for the Next Driver to See the Fix

The next driver should not have to guess. Make sure that:

- Paper DVIR books get updated with the repair certification

- eDVIR apps show the defect as corrected, tied to a date

- Fleet customers can get a copy of the repair record quickly if they ask

Holiday chaos or not, if the next driver can't see that a defect was handled, your process isn't done.

Holiday DVIR Checklist for Shop Owners

Use this as a quick "am I really covered?" list before and during the season:

- Every DVIR with a safety defect becomes a work order the same day

- Safety defects are clearly flagged as dispatch-blocking

- No unit with a red-tagged DVIR defect goes out without a signed repair decision

- Tech notes explain what was found and what was fixed, not just "OK now"

- DVIR certification is part of the job-closing process, not an extra step

- You can pull DVIR → work order → sign-off for any December defect in a few minutes

If any of those answers are "sometimes," that's your risk window.

The Real Test

If an inspector or attorney asked you next spring:

"Show me every DVIR defect from last December and how each was repaired and signed off."

Could you produce a clean trail from DVIR to work order to certification without digging through boxes and inboxes?

If not, the problem isn't holidays. It's that DVIRs and work orders aren't truly connected in your process.

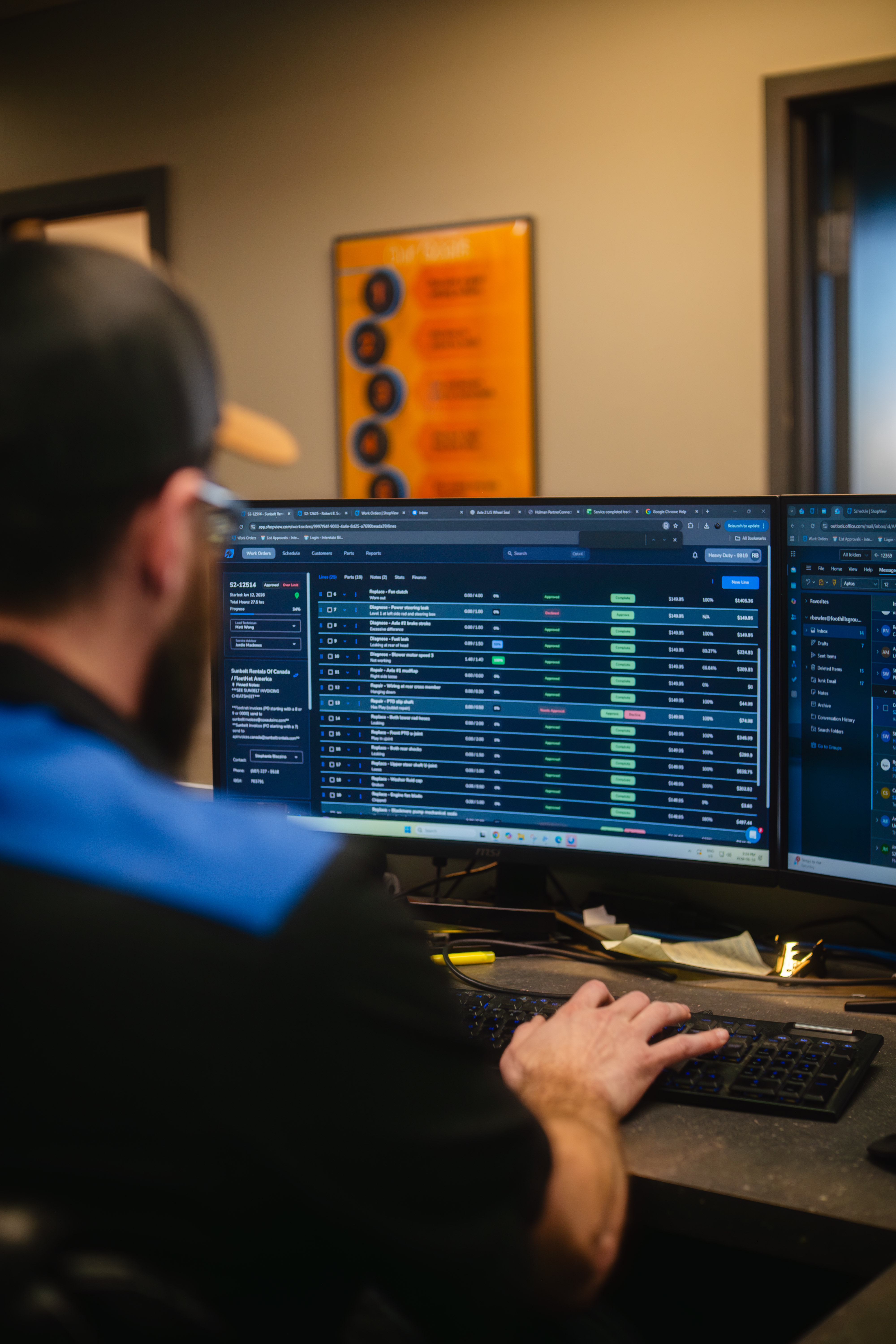

If you want to see how that connection looks when it's built into one system - DVIR complaints turning into structured jobs, jobs forcing sign-off, and everything tied to the unit history - you can walk through it inShopView's work order & status demo.

That's how DVIR → work order compliance survives holiday staffing - by design, not by luck.

Ready to transform your shop?

We've been in the heavy-duty truck repair business for 20+ years, so we know what slows shops down. That's why we built ShopView—to eliminate the bottlenecks.